Customers and friends who have customized non-woven bags should find such a phenomenon. When we customize non-woven bags, the minimum order quantity of non-woven bag manufacturers is generally 5,000, but the more exquisite color-coated non-woven bags The minimum order quantity of cloth bags is 10,000 pieces. Why is there such a big difference in the minimum order quantity of non-woven bags of different types, styles and colors?

The reason why the MOQ of non-woven bags is so different is related to many factors, the most important of which is the production process used by the manufacturer. At present, the most commonly used production process for non-woven bag printing is screen printing, and screen printing is manually operated by printing workers. The minimum order quantity of non-woven bags printed in this way is relatively low, generally 5000 orders. However, in this way, only non-woven bags with simple patterns can be printed, and gradient colors cannot be printed. And because it is manually operated by workers, the labor cost is high.

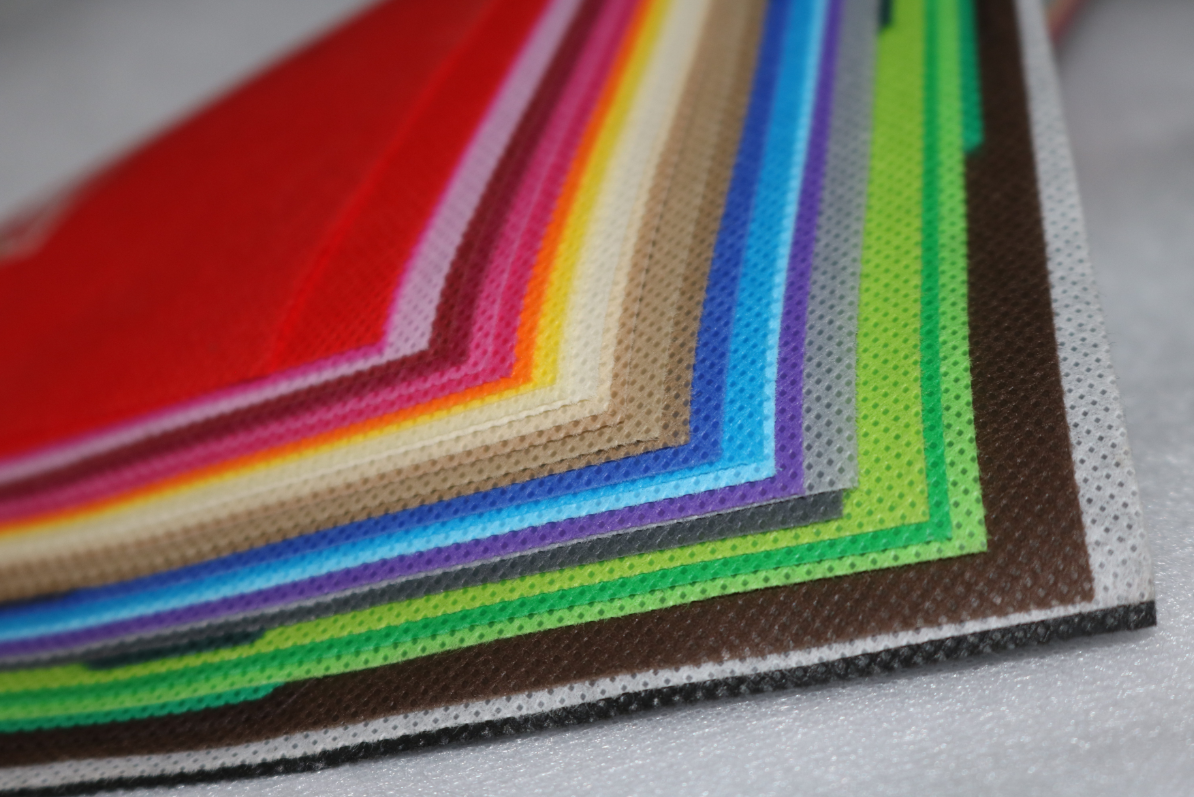

If you want to make non-woven bags or film-coated bags with richer and more beautiful colors, you need to use gravure letterpress printing. Using this method, you need to debug the pattern in the rapid flow of raw materials, and the richer the pattern color, the more the plate color, and the modulation The more complex it is, the longer it takes, and the more waste of raw materials it causes, which will cause the price of the finished product to rise, and the scrap rate will be higher in the case of a small number of custom-made products, so this kind of non-woven coated film is required. Bags or nicely patterned non-woven bags have a larger MOQ.

<< previous

next >>